Scan Tools are a great help to motor mechanics with finding faults in a vehicle. They cover all aspects of a vehicle, and gives you live data of which individual component is doing, without having to get dirty and manually check it yourself. With this data, a mechanic could check the parameteres of a component and do the required work to fix it by either replacing it, or by taking it out and seeing what is wrong with it.

Our task was to use a Scan Tool on a vehicle and record information on how the car is running. The scan tool we used was a LAUNCH, which we used on my 2001 Toyota Corolla 4A-FE

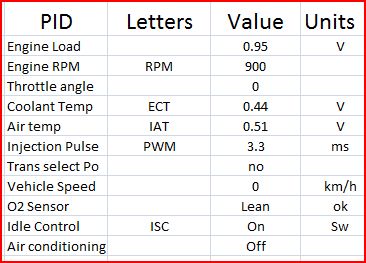

Here is the data that we collected

2.0

Check the scan tool for any faults

Our next task was to check for any fault codes that may have turned up on the scan tool. I connected a jumper wire across THW and E1 to get the codes to show up, but as it turned out, my car was fine so we recorded 0 faults.

3.0

If there are no faults, create a fault by getting the lecturer to disable a sensor

Then we created a fault in the car by disabling a sensor. I hopped in my car with the key on, the check engine light was on, and was giving me a code of.... 3 long...pause..1 short...repeat... which indicates code 31. I checked my Toyota Service Manual and fault code 31 is a faulty vacuum sensor. We then recorded the data on the scan tool to see what data has changed.

6.0

Do a visual inspection of the faulty sensor

We then visually checked if there was a problem with the MAP sensor, and we saw that it was disconnected.

7.0

Fix the problem and clear the fault code

We plugged the MAP sensor back in, and then disconnected the battery to clear the memory. After connecting the battery back up, we checked the engine light again and it registered as all clear.

11.

Why is live data important when fault finding?

Live data is very important because if you have knowledge into how the components work and what they should be doing, yo can see if a component is not doing it's job by checking the live data screen. For example if your engine was running too rich, and the TPS sensor was reading 3V at idle, I can immediately detect there is something wrong with the TPS because it's should be from 0.5- 1V at idle

12.

Why are parameters good when checking the condition of components?

Parameters are good when checking live data because it tells us what voltage output or what resistance the component should be at a time. If the parameters are not met, there is something wrong with the component.

13.

How useful is the scan tool at finding faults

Scan tools are a great aid with fault finding because it locates the system fault, and will tell us when the problem has been fixed.